She

is amazingly tight and looks in better shape than Ricochet did when I

viewed her. I'll be getting her in the shop as soon as the

transport company can get her to me. Here is a post I did

about her with some photos.

More to come when I get them.

It

spins freely, seems to have good compression and has both

compression relief and glow plugs. My big old Perkins has neither. The

heat exchanger is toast.

It

spins freely, seems to have good compression and has both

compression relief and glow plugs. My big old Perkins has neither. The

heat exchanger is toast.

While

the boys worked with heat guns on the paint, wooding the old

girl, I went after the seams. This job is not entirely painless.

While

the boys worked with heat guns on the paint, wooding the old

girl, I went after the seams. This job is not entirely painless.

The

compound the previous folks used is like an epoxy, hard as a rock

and sticks well to the wood on whatever side it stuck to. I have to

chip it loose and then reef it out. I'll post a video tonight showing

the painful, tedious process.

The

compound the previous folks used is like an epoxy, hard as a rock

and sticks well to the wood on whatever side it stuck to. I have to

chip it loose and then reef it out. I'll post a video tonight showing

the painful, tedious process.

Sometimes

I get lucky with a long run, usually not...

Sometimes

I get lucky with a long run, usually not...

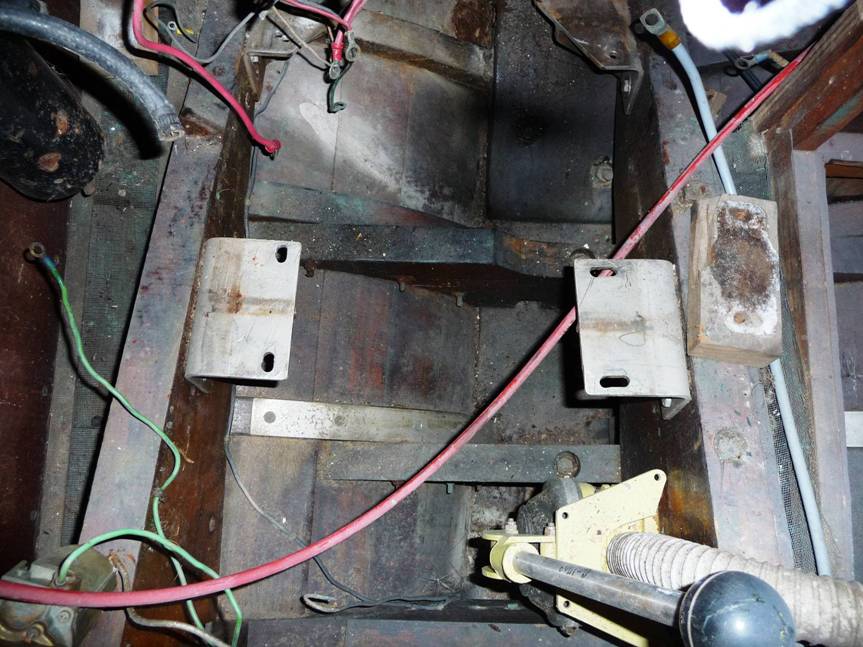

There

were some dubious repairs done to her in the past, such as this

thru-hull plug with fasteners set in seams. I'll have to scarph in

planking to fix that.

There

were some dubious repairs done to her in the past, such as this

thru-hull plug with fasteners set in seams. I'll have to scarph in

planking to fix that.

They

also has drilled holes in the shaft strut in order to make sure

the goop they faired it with stuck. C'mon..., drilling holes in

perfectly good, irreplaceable bronze for THAT? Somebody needs an

a$$kicking...

They

also has drilled holes in the shaft strut in order to make sure

the goop they faired it with stuck. C'mon..., drilling holes in

perfectly good, irreplaceable bronze for THAT? Somebody needs an

a$$kicking...

Of

course, the goop they stuck on caused it's own issues that I'll have

to deal with.

Of

course, the goop they stuck on caused it's own issues that I'll have

to deal with.

The

seams do clean up nicely, if well opened. Seeing as how see has 9"

centers on the ribs, I'm not worried about caulking too hard. This is

the best built Kettenburg I've yet seen, much stouter than the K-38's

or PCC's.

The

seams do clean up nicely, if well opened. Seeing as how see has 9"

centers on the ribs, I'm not worried about caulking too hard. This is

the best built Kettenburg I've yet seen, much stouter than the K-38's

or PCC's.

More

shoddy work in the sisters and transom where they didn't sink the

fasteners enough to set bungs. I'll have to fix this, especially on the

transom where she'll be bright.

More

shoddy work in the sisters and transom where they didn't sink the

fasteners enough to set bungs. I'll have to fix this, especially on the

transom where she'll be bright.

The

boys have been making good progress as well.

The

boys have been making good progress as well.

So,

all in all, it's been a bit tedious but steady. She'll go inside

the shop next week for further work as the yard gets nervous with all

of the scraping and carrying on we're doing. We do vacuum up a couple

times a day though. Yes, that's right. We vacuum pavement and dirt to

clean up the paint chips. I reckon we have the cleanest dirt in the

PNW....

So,

all in all, it's been a bit tedious but steady. She'll go inside

the shop next week for further work as the yard gets nervous with all

of the scraping and carrying on we're doing. We do vacuum up a couple

times a day though. Yes, that's right. We vacuum pavement and dirt to

clean up the paint chips. I reckon we have the cleanest dirt in the

PNW....

Boat

photos:

Here

are pictures of the broken and cracked ribs either from old age or the

transit.

and

and

Still looks kinda orange to me...

The hull is detailed and ready for stain, mostly. I put some on to see

if the customer likes it.

Still looks kinda orange to me...

The hull is detailed and ready for stain, mostly. I put some on to see

if the customer likes it.

I

didn't like any of the stock colors so what you see is a two step

process. The base stain followed by a light wiping of a Mahogany Red

stain.

I

didn't like any of the stock colors so what you see is a two step

process. The base stain followed by a light wiping of a Mahogany Red

stain.

and

and

I still have to hand make this rudder trim piece from that gorgeous

chunk of Sapele.

I still have to hand make this rudder trim piece from that gorgeous

chunk of Sapele.

Things

are heating up quickly.

Things

are heating up quickly. Port

seams

Port

seams

Starboard

seams

Starboard

seams

Finished

lower seams

Finished

lower seams

Finished

upper seams

Finished

upper seams

I

will surely be happy when these seams are completely done. It's been a

chore beyond compare. There's paint in the bilges but it's not ready

for prime-time yet so those shots will have to wait till next weeks

update.

One thing we found is absolutely not a single valve on any of the thru

hulls. Just hoses. We'll be changing that....

I

will surely be happy when these seams are completely done. It's been a

chore beyond compare. There's paint in the bilges but it's not ready

for prime-time yet so those shots will have to wait till next weeks

update.

One thing we found is absolutely not a single valve on any of the thru

hulls. Just hoses. We'll be changing that.... This

afternoon, I started applying seam compound. Nasty, NASTY stuff to work

with. Very stiff and clay like. It doesn't like sticking to the inside

of the planking and will sometimes fall out just when you think ya have

it set. Very oderifous as well so ya know you've been at it too long

when ya can't smell it anymore.

This

afternoon, I started applying seam compound. Nasty, NASTY stuff to work

with. Very stiff and clay like. It doesn't like sticking to the inside

of the planking and will sometimes fall out just when you think ya have

it set. Very oderifous as well so ya know you've been at it too long

when ya can't smell it anymore.

Yeah,

that's pretty ugly but I'll clean it up tomorrow after it's cured a

bit. Jay was on the same side still paying seams further up the hull.

Yeah,

that's pretty ugly but I'll clean it up tomorrow after it's cured a

bit. Jay was on the same side still paying seams further up the hull.

He

came in with a Samurai topknot today, interesting doo. Zach was forward

finishing the seam along the stem post that runs all the way from the

back of the keelson.

He

came in with a Samurai topknot today, interesting doo. Zach was forward

finishing the seam along the stem post that runs all the way from the

back of the keelson.

Charles

was hanging out by himself to Starboard working seams.

Charles

was hanging out by himself to Starboard working seams.

Me?

I was relaxing some kinks after laying in that section of compound. My

hands were sore today.

Me?

I was relaxing some kinks after laying in that section of compound. My

hands were sore today.

Them

there Boys get to join the compounding fun starting tomorrow....

Anyways, that's another week and at least it looks like we're making

headway at last.

Them

there Boys get to join the compounding fun starting tomorrow....

Anyways, that's another week and at least it looks like we're making

headway at last. I cut the piece and fitted it in with shims at first.

I cut the piece and fitted it in with shims at first.

I

bored the new screw holes prior to glue up and then mixed epoxy and

mahogany sawdust. I set the scarph joint with screws and let it cook a

bit before I had big Zach press the new plank flush while I drove

screws.

I

bored the new screw holes prior to glue up and then mixed epoxy and

mahogany sawdust. I set the scarph joint with screws and let it cook a

bit before I had big Zach press the new plank flush while I drove

screws.

It flushed out nicely.

It flushed out nicely.

The boys worked the seams again today.

The boys worked the seams again today.

I should do these last three salon ribs tomorrow.

I should do these last three salon ribs tomorrow.

and so it goes....

and so it goes....